Product Design and Development

We can offer a full product development service. Our team will work together with the clients brief to create concept artwork and drawings for approval.

Our experienced engineering department will work with the client to consider the development process from every aspect, including the best path to mass production of the product. Our expertise will allow us to optimize this process and produce final products which will be the leaders in the market. Once the best procedure has been established, we will create the prototype samples.

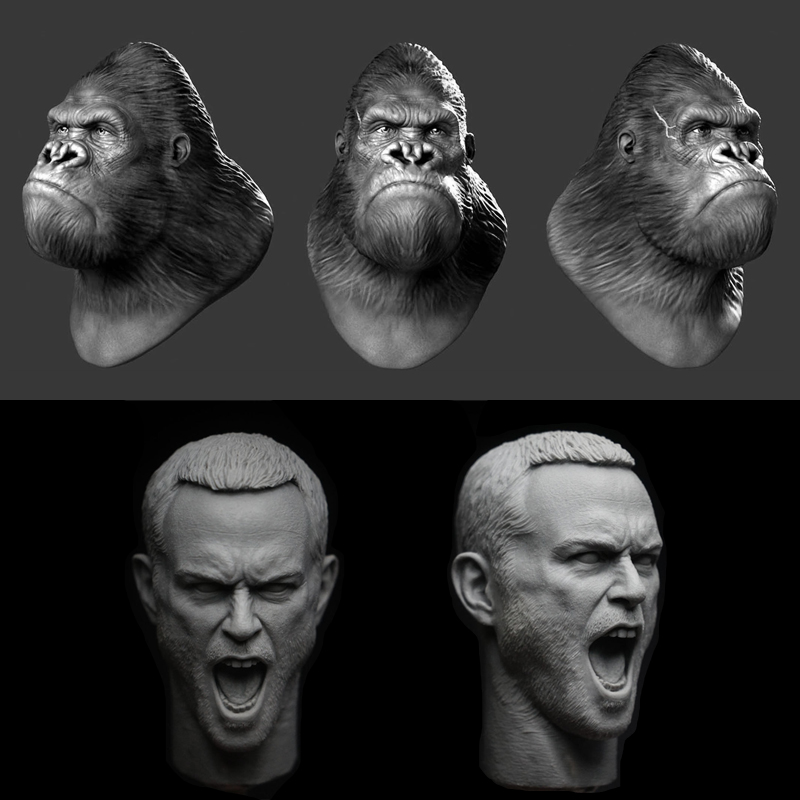

3D Modelling and Sculpting

We are continually keeping pace with technology, allowing us to create anything that can be imagined. Our team of 3D artists can either laser scan a sample so a prototype can more easily be modified, or we can create a drawn design to be rendered with the latest 3D software. Our state of the art printers can then output the model for prototyping.

With this model, we can study the product's structure and intended movement and adjustments can easily be made on the computerised 3D model. This combination of scanning and 3D modeling is a more efficient method for prototyping and greatly speeds up the process.

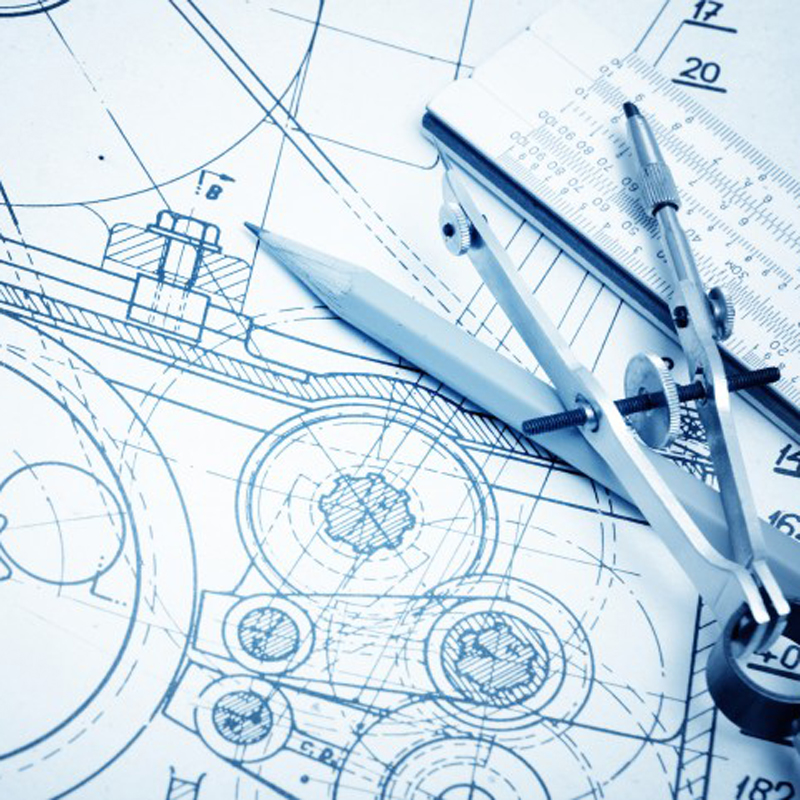

Tooling Design

We have our own in-house mould shop with advanced equipment and precision machines. Our fully-integrated CAD systems is used for mould layout design, and data is transferred to highly precise mould development machines such as CNC and EDM. We have the capability to make high quality moulds precisely for complicated parts with less tolerance, hence efficiency is increased allowing a smoother path to mass production.

Engineering Design

Product testing is an important process in development. Each product will go through various sampling, verification and approval stages to ensure the feasibility of mass production. We can also advise workable options in helping customers to resolve problems found during the testing process.

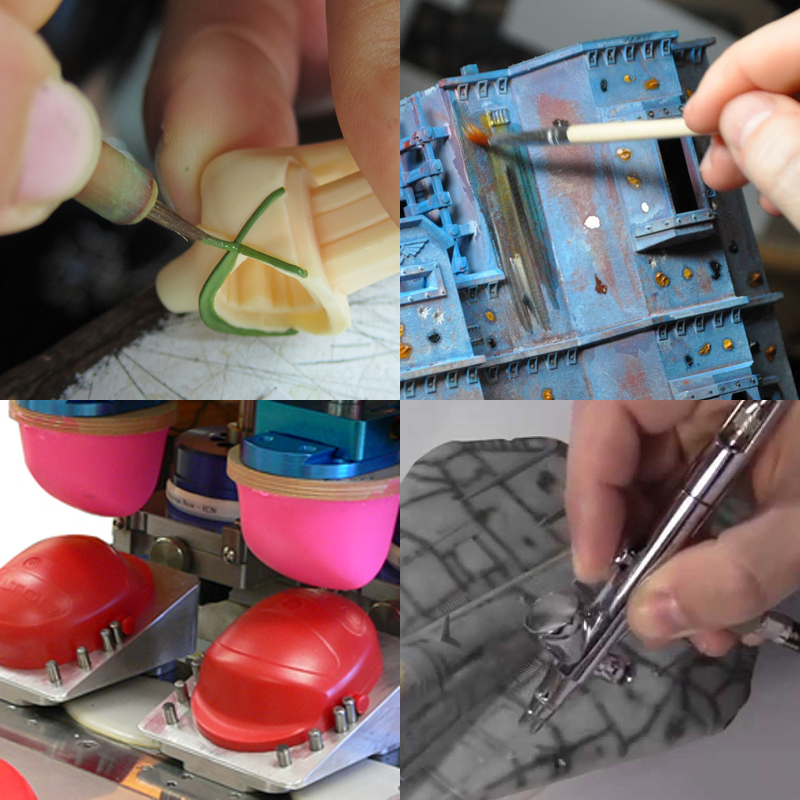

Production Process

We have different materials and production methods and we can choose the right procedure and materials to deliver the highest quality product. Each process has different advantages and we will work together to determine the best one for each customer and product. Our expertise includes:

— Plastic injection moulding

— Die-cast injection moulding

— Roto-casting

— Slushing

— Fabric cut and sew

Painting Decoration

We have a variety of painting decoration techniques for different effects and requirements. Each decoration process is designed for the specific product and inspection insures that all the works-in-progress and finished products are consistent and of the highest quality. These processes include:

-- Masked color spraying

-- Detailed highlight weathering and paint washing for realistic effects

-- Tampo pad printing for fine detail markings

-- Skilful free-hand painting for tiny touch-up details

Management system & quality assurance control

We have the ISO 9001;2000 certification for manufacturing facilities to assure each process is up to the highest quality standards. We can also arrange a unique system based on our customer's specific requirements.

There is comprehensive testing, inspection, and process control implemented at various stages of production, including:

— Incoming material inspection

— Sharp tools management control

— Metal detector inspection

— Inline process quality control

— Quality assurance control

— Finished goods inspection